CNC Laser Cutting

CNC Laser Cutting Machine: Where Precision and Technology Meet

As technology evolves, industries are focusing on various innovations to increase efficiency in production processes and achieve more precise results. One of these innovations is CNC (Computer Numerical Control) laser cutting machines. CNC laser cutting is a technology that provides high precision and speed in cutting metal and other materials.

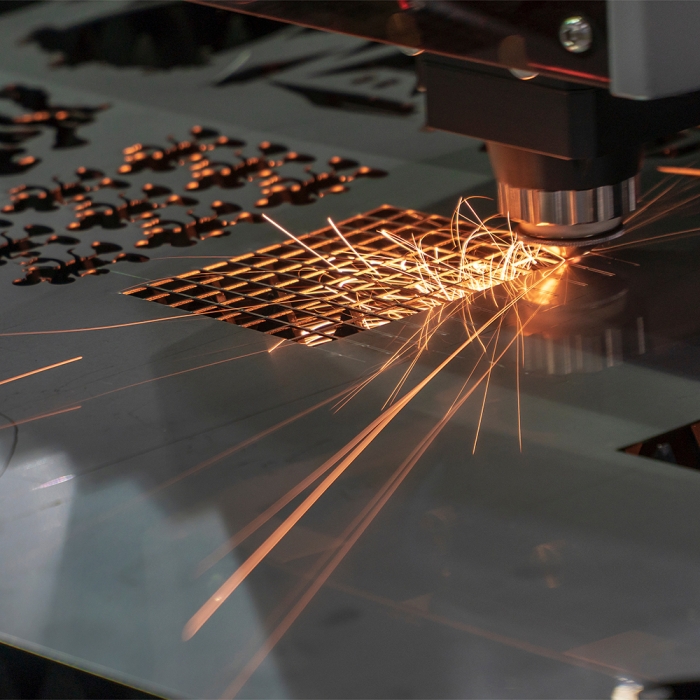

Working Principle: CNC laser cutting machines enable a laser beam to be directed onto the material through a computer-controlled system. This system makes it possible to cut the material in the desired shape. The laser beam creates high-energy rays on the material, cutting and shaping it. This process occurs automatically according to the cutting pattern determined by the computer.

Precision and Speed: CNC laser cutting machines have the ability to work with high precision. This means they can easily process complex designs, fine details and sharp corners. In addition, the speed of laser technology accelerates production processes, allowing more material to be processed in a shorter time.

Flexible Design and Production: CNC laser cutting machines provide flexible design and production opportunities in various industrial sectors. These machines can meet both custom designs and personalization as well as mass production requirements. This gives manufacturers the advantage of being able to respond quickly and effectively to customer needs.

Sustainable and Economic: CNC laser cutting offers a solution for sustainable production by keeping material waste to a minimum. In addition, high precision and speed provide an economical production process by saving energy and time.

CNC laser cutting machines continue to be an important tool leading the technological evolution of industries and raising production standards. The advantages offered by this technology make it indispensable for companies that want to increase success and efficiency in modern production processes.

| PRODUCT TYPES | THICKNESS (mm) | WIDTH (mm) | LENGTH | ||

|---|---|---|---|---|---|

| Min | Max | Min | Max | ||

| GALVANIZED | 0.30 | 2.00 | 1000 | >1500 | 3000 |

| DKP | 0.40 | 2.00 | 1200 | >1500 | 3000 |

| HRP | 1.50 | 10.00 | 1500 | >1500 | 3000 |

| BLACK SHEET | 1.30 | 35.00 | 1000 | >1500 | 3000 |

Working Area (6 KW - 12 KW)

- X Axis : 1500

- Y Axis : 3000